Creativity is the key to success. UV printing technology is one such invention that has revolutionized several industries. UV printing is no longer simply a cutting-edge fad; it is now essential to sectors including manufacturing, packaging, and advertising. However, why is UV printing technology being used in these sectors? Let's explore this amazing technology's depths.

Ultraviolet Printing

UV printing is a state-of-the-art method that uses UV light to rapidly dry or cure adhesives, varnishes, and ink. All kinds of businesses find UV printing to be an appealing option due to its many benefits over conventional printing techniques, which depend on heat or air drying.

Unmatched Print Quality

Achieving unmatched print quality is one of the main goals of UV printing. Images are clear and colorful because the ink's rapid cure prevents it from being absorbed by the substrate. UV printing is perfect for applications like product packaging and advertising materials where aesthetic appeal is crucial because of its high resolution and color fidelity.

Improved Sturdiness

In many businesses, particularly those that deal with labels, outdoor signs, or industrial components, durability is a crucial consideration. The durable, scratch-resistant prints produced by UV printing guarantee that text and images will hold up even under challenging conditions. For labels, signs, and nameplates, UV printing is the recommended option primarily because of its durability.

Versatility in Substrates

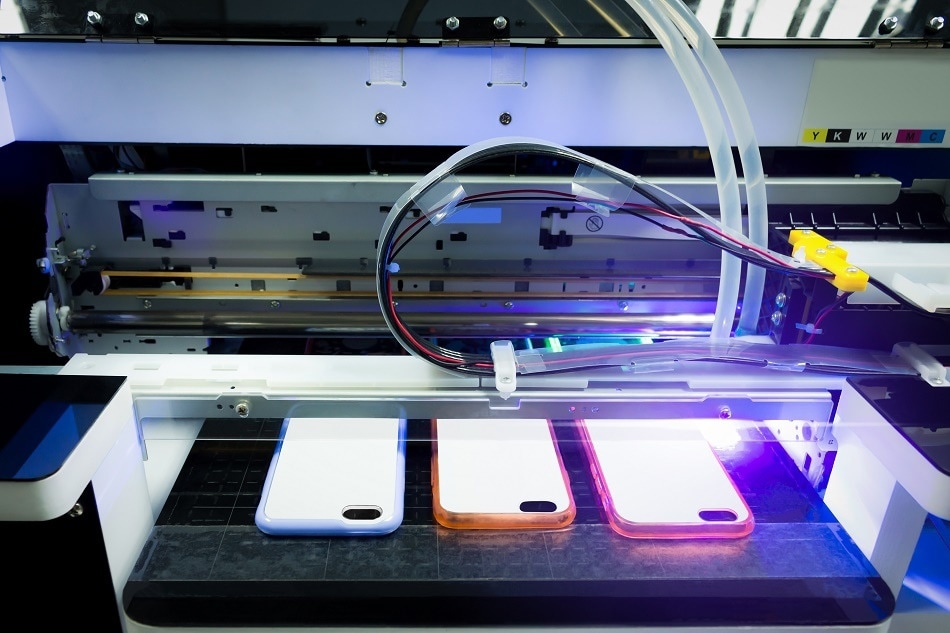

The fact that UV printing is compatible with a variety of substrates serves as another important goal. When printing on a variety of materials, including paper, plastic, glass, metal, and wood, UV printing may stick to the surface and provide fantastic results. This adaptability creates a plethora of opportunities for companies in many industries, such as the production of unique package designs or elaborate graphics on unusual materials.

Sustainable Printing

When sustainability is a consideration, UV printing has become popular for its eco-friendliness. Conventional solvent-based inks contribute to air pollution by releasing volatile organic compounds (VOCs) into the environment. In contrast, UV printing employs inks that are instantaneously dried by UV light, resulting in little to no volatile organic compound emissions. Because of this, UV printing is a sensible option for firms that care about the environment.

Enhanced Rate of Production

In the world of production and manufacturing, time equals money. The quick curing method of UV printing significantly cuts down on drying periods, enabling faster project turnaround. The packaging and label manufacturing businesses, in particular, benefit greatly from this enhanced production speed since they need printing in large quantities.

Price-Performance

Although UV printing technology may have a greater upfront cost than other processes, there is no denying that it is more cost-effective in the long run. Cost reductions over time are a result of shorter manufacturing periods, less ink used, and less waste through quick curing. Many companies discover that the initial outlay is repaid in the form of increased productivity and lower operating costs.

Conclusion:

Technology known as ультрaфиолетовaя печать, or ultraviolet printing, has several uses across a range of sectors. Due to its exceptional print quality, increased durability, versatility on a range of substrates, and environmental friendliness, it is a top option for companies worldwide. In addition, the technology's increased pace of production and long-term cost-effectiveness reinforce its revolutionary status.