Technological developments are bringing about major changes in the wood equipment industry. The production of wood goods is changing due to advancements in automation, software, and materials. This development improves wood processing accuracy, efficiency, and waste reduction. The industry has both possibilities and obstacles as it adjusts. It is essential for anyone involved in the wood machinery industry to comprehend these developments.

Automation's Ascent in Wood Processing

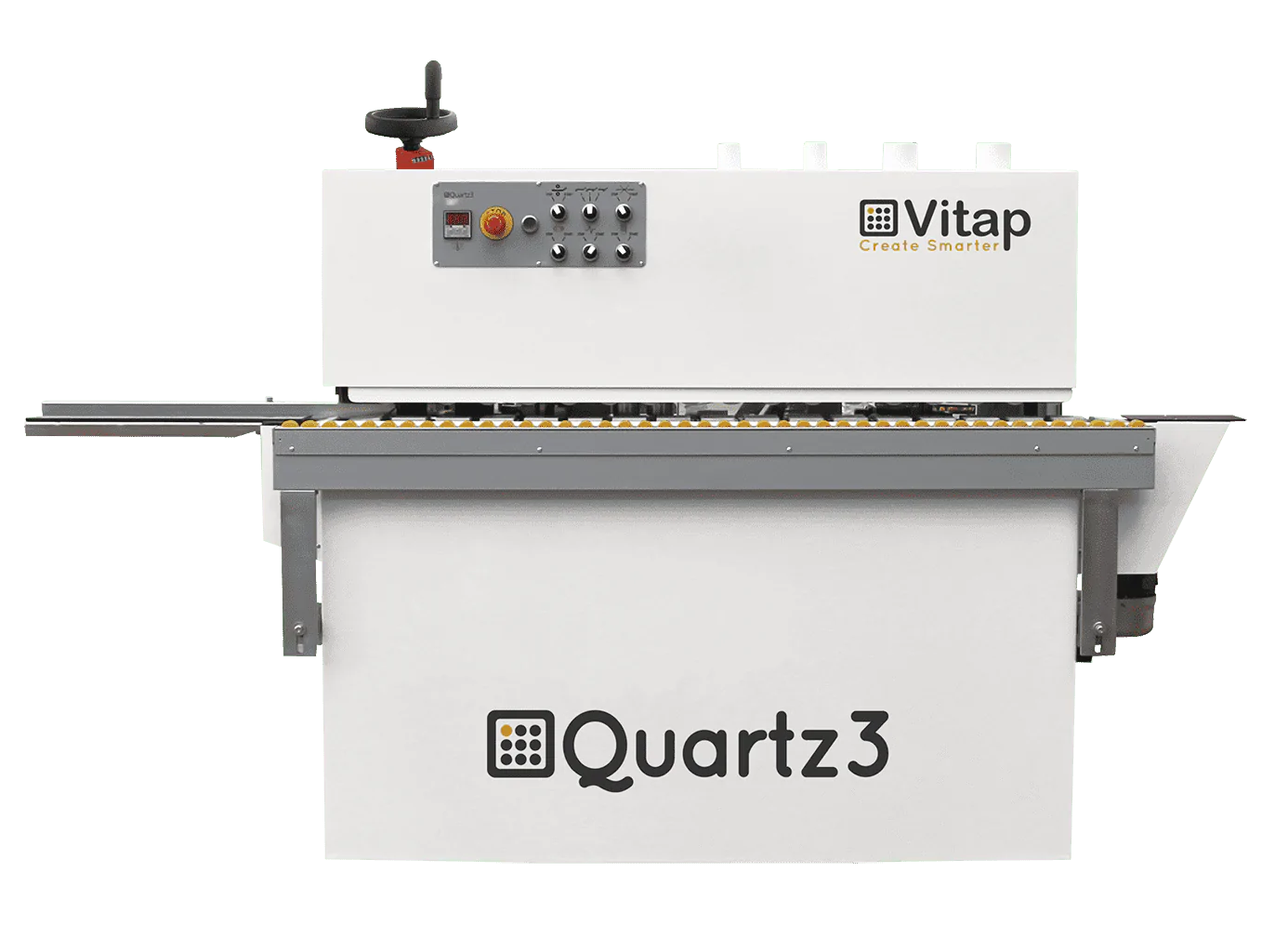

For maquinaria madera, automation has changed everything. Complex activities can be completed by modern robotics-equipped robots with little assistance from humans. This speeds up production and lowers labor expenses. Additionally, automated mechanisms guarantee that each product is of constant quality. Manufacturers are thus more equipped to satisfy rising needs.

Smart Technology Integration in Machinery

Wood equipment is being revolutionized by the use of smart technologies. Real-time data sharing and communication between machines are made possible by IoT (Internet of Things) devices. Predictive maintenance and improved equipment performance monitoring are made possible by this link. By using data analysis, manufacturers can reduce downtime and save expensive repairs. Additionally, smart technology helps to optimize manufacturing processes, which results in higher productivity and less waste.

Increased Accuracy using CNC Equipment

Wood processing has reached new heights thanks to Computer Numerical Control (CNC) devices. Previously difficult to do, these tools enable accurate cuts and complex patterns. Manufacturers can reliably and swiftly create intricate designs using CNC technology. This accuracy creates new opportunities for woodworking inventiveness. The design and functionality options will only increase as technology advances.

Eco-Friendly Innovations and Sustainable Practices

A major area of concern in the wood equipment industry is sustainability. Technological developments have produced environmentally friendly materials and procedures. These days, manufacturers are spending money on equipment that reduces their environmental effect. Innovations such as recycling garbage and using biomass energy are becoming increasingly common. In addition to reducing waste, these methods improve the industry's reputation for being ecologically conscientious.

The Wood Machinery Industry's Future

Wooden equipment has a promising and bright future. The industry will see even better efficiency and capacities as technology develops further. It's conceivable that traditional approaches will change and include contemporary strategies. To remain competitive, manufacturers will have to accept these changes. In order to guarantee the sustainability and quality of wood products, the emphasis will be on fusing technology and craftsmanship.

Conclusion

The future of wood equipment is greatly impacted by technological improvements. The industry is changing as a result of advancements including automation, smart technology, CNC accuracy, and sustainable practices. For stakeholders, the continuing transition offers both possibilities and problems. The industry will keep changing as it adjusts, emphasizing effectiveness and quality. Exciting advancements in the production and processing of wood products are anticipated in the future.